Speeds of 700 Mbps using 80 MHz channels were achieved during the trial and low latency applications, like video calling and video streaming, performed well with the average latency being less than 6ms and the maximum observed latency was 11ms.

The WBA claims that these results prove that Wi-Fi 6 infrastructure can operate well in the presence of interference and noise in a complex and challenging factory environment while delivering high quality services for monitoring and maximising machinery performance, minimising downtime, and improving communications on the factory floor.

The phase I trial involved the following tests (among others), which were performed using devices such as smartphones, tablets, laptops and webcams equipped with the Broadcom BCM4375 and Intel AX200 Wi-Fi 6 chipsets::

- 4k streaming from a webcam mounted on machinery within the factory

- 4k YouTube streaming from a laptop with Intel AX200 chip

- Uploads of very large video files over Wi-Fi

- Roaming, latency and persistent connectivity during Wi-Fi video calling using smartphones equipped with Broadcom’s BCM4375 chip

- Augmented reality testing of machinery using devices with Wi-Fi 6 chipset

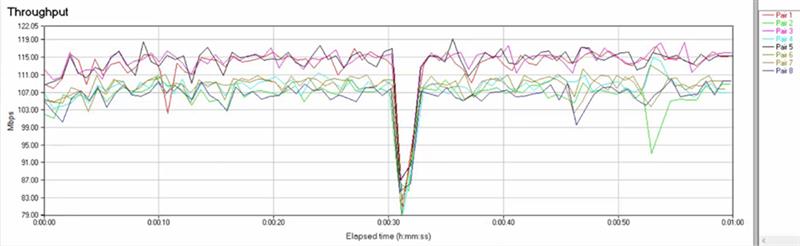

A graph showing some of the video call test results – the device making the call was also running background traffic as it roamed around the factory floor. The dip was caused by the client roaming from one AP to AP, while maintaining connectivity and high throughput.

The Wi-Fi 6 technology had to provide total connectivity across a large-scale, complex factory environment, delivering real-time high bandwidth communications, with very low latency and clear prioritisation, to enable improved synchronisation of factory floor machinery and equipment with centralised monitoring and control systems. Previous implementation tests with older Wi-Fi technology failed to work in Mettis’ challenging factory environment.

The trial took place at the 27-acre Mettis Aerospace facility in the West Midlands in collaboration with WBA member companies including Broadcom, Cisco, iBwave and Intel as well as Concurrent Engineering and Keysight. Mettis Aerospace supplies companies such as Airbus, Boeing and Rolls-Royce.

As part of the project, Cisco provided 11 Catalyst 9100 access points (along with WLC and POE Catalyst switches) configured to ensure persistent and consistent signal reliability throughout the day under regularly changing conditions. iBwave performed a site survey of the manufacturing floor, recorded noise level measurements (with machinery on and off) and gathered essential details about obstructions and the variability of the environment. The WBA says that this was critical to the success of the project due to the prevalence of metal surfaces that can disrupt radio (RF) connectivity.

Cisco and Mettis worked together using survey results to guide the deployment of the access points and to optimise the configuration for the environment. Using devices that included smartphones, tablets, laptops and webcams – equipped with the Broadcom and Intel Wi-Fi 6 chipset, a series of tests were performed using Ix Chariot software to assess and troubleshoots the networks and the applications both before and after the deployment.

Concurrent Engineering’s PTC Vuforia augmented (mixed) reality software was used by the maintenance team to enable ‘walk- by’ machine monitoring (shown above). This test showed it was possible to position a tablet alongside a piece of machinery and get an instant reading of the real-time pressure and performance of the machine. In future, this is expected to speed up fault-finding and diagnosis, aid preventative maintenance and minimise machine downtime.

Mettis was already collecting data from its 12,000t press so this required no additional time to gather. The company then had to then present the data for the app to be used over the Wi-Fi 6 network and this took no more than a day. Concurrent Engineering then used the data to create the mixed reality app using relevant software.

Phase Two of the Wi-Fi 6 trial will focus on further tests of the Mixed reality applications and IoT sensing of key assets.

“The completion of this initial phase marks a significant milestone for the adoption of Wi-Fi 6,” said WBA CEO, Tiago Rodrigues. “The Mettis facility is an especially challenging environment for wireless communications with furnaces, presses and heat, a lot of moving heavy machinery and the presence of dust and in-air particulates. Nevertheless, the field tests in this highly charged atmosphere have proven that Wi-Fi 6 technology works well and can play a vital role within the industrial enterprise and IoT ecosystem. If Wi-Fi 6 can deliver highly reliable, high quality and high bandwidth communications in this type of factory environment, then it can deliver it almost anywhere,” he added.

“The Wi-Fi 6 infrastructure installed as part of the trials has exceeded our expectations in terms of performance, reliable connectivity and consistent coverage across the target area,” said Dave Green, head of IT, Mettis Aerospace. “We are seeing immediate benefits in terms of the data we’re now able to collect and use. Moving forward, we will be able to vastly increase the data we collect from devices across our business, enhancing our manufacturing processes, reducing variability and increasing productivity.”